I previously touched on the need for three phase power when I mentioned the coming of a 10HP planer in this dust collection post. This post outlines what it is, what are the options I evaluated for getting it in my shop, and what I ultimately did.

What is Three Phase Power

Most homes (and home workshops) have single phase power, which is power delivered over one “hot” wire - the phase wire - and one neutral wire providing a return path for that power. In the US, the hot wire has a voltage of 120 volts or 120v. That phase wire delivers alternating current (AC), which means that rather than being a continuous source of power like a battery, the voltage as cycling up and down, 60 times a second (or at 60 hertz, 60Hz).

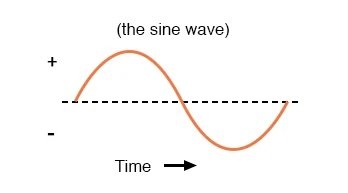

That cycling looks like a sine wave - and 60 of those are repeated each second. But as you can see from that sine wave, the voltage (and thus, the effective power delivered) to a motor zeros out twice each cycle, or 120 times per second. Without a continuous source of power, a motor is less efficient - it needs extra mass to keep the inertia going when the electrical power drops to zero. So if instead of getting just that single sine wave, we could get a second - or even a third! - sine wave that was offset from that first wave by some amount, then we’ll get a more continuous flow of power, and can build a more efficient motor.

In fact, if those three phases are offset perfectly - offset by one third of a cycle each - then the effective power delivered by all three of those phases in combination is continuous. And instead of talking about offsets in terms of a third of a cycle, we can talk about offsets in the context of degrees of a circle. So a third of a cycle is third of 360°, or 120°. Thats where the references to degrees comes in with three phase power.

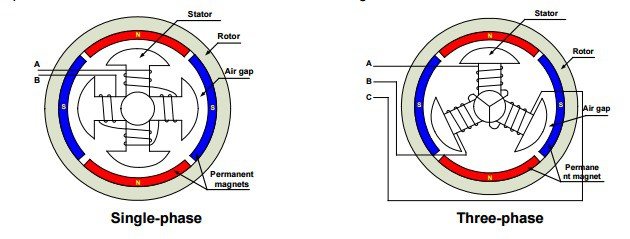

Electrical flow produces a magnetic attraction; this is the foundation of what enables a motor to spin. The most basic design of a single-phase motor contains a single-coil each for the rotor and stator. As the alternating current passes through these coils, it changes direction every half-cycle of the sine wave, the rotor and stator, in turn, attract and repel each other, producing a continuous revolution of the rotor. Because of their relative simplicity, single phase motors are less expensive, but they max out at about 5HP of torque, they require additional components to “start” them, and they do not have high torque when they are starting up.

Instead of having a single corresponding pair of coils for the rotor and stator, a three phase motor has three pairs of coils, spaced 120° apart around the rotor shaft, each connected to one of the active wires of the 3-phase power. As the rotor completes one 360° revolution, each coil is attracted and repelled three times, producing a higher-torque, higher-efficiency operation compared to a single-phase motor.

Because of this design, 3-phase motors have significantly higher efficiency at converting electrical to mechanical energy, and therefore lower operating costs. They are inherently self-starting, and because of their higher torque, especially during starting, they are ideal for heavy industrial applications.

Note that most homes also have a second “hot” wire, which is used together with the first wire to provide 240 volts, necessary for larger appliances like electric ranges, car chargers, pool pumps, or say, a table saw. But that second wire is not a second phase; rather those two wires are a single phase from a center-tapped transformer from the utility - you could conceptually think of this as +120V and -120V, so that the difference between them is 240V, or the difference between either of them and ground or neutral is 120V.

Options for Three Phase Power in Home Workshops

But power is in fact generated (and transmitted) in three phases - for the why, as well as lots of interesting history and engineering, read about The War of the Currents between Thomas Edison & George Westinghouse. Getting a power upgrade from your utility is not all that unusual as you, say, update the electrical panel in an older house from 80A to 200A to address modern day needs; why not just get the utility to drop 3-phase power to you instead of single phase?

If you are in an industrial or commercial location, three phase power from the utility is often already wired in, or can potentially be made available. But in residential / home shop environments, three phase power is rarely available: the final distribution wires in residential locations may actually be just of a single phase, so there are not wires from the other phases to deliver to you. Or perhaps the utility may do for a fee. But in California, this is just not an option for a residential shop. So we have to look at phase converters: if you can’t get three phase power from the utility, then you just need to generate it yourself!

Two things are needed to generate the additional phases: some sort of storage mechanism to allow you to “time shift” some power; and some mechanism to convert that time-shifted power back into a sine wave. This can be done by a “rotary converter” or a “digital converter”.

Rotary Converter

You can think of a rotary converter as just a large single phase motor that is spinning a three phase generator. That “storage” mechanism is provided by the rotational inertia of the motor; the sine wave generation is done by the generator itself. Rotary converters usually have some additional components between the generator and the output to filter noise / clean up the power line, but it’s essentially that simple, and because of their comparative simplicity, they are typically the cheaper of the two options available.

But you need to find space for the large motor / generator, which also generates noise (and vibration), so depending on the shop, you may wish to locate this outside, potentially inside an enclosure so as to not upset your neighbors and to stay protected from the elements. And given that location, you may need to run a long electrical line to / from the converter, which might require you to upsize the conductors for long runs.

This was my situation: if I had gone this route, I would’ve mounted this outside next to my air conditioner, but far away from my main electrical panel. Running all the extra conduit and oversized conductors would have been very expensive in materials alone.

Rotary converters also have two other disadvantages: higher “idling” costs because that motor must be spinning all the time you might turn on / off your three phase machines, and they produce “dirtier” power with more spikes and transient noise due to the internal moving parts.

North American Phase Converter is a supplier in this space; their 10HP models range from $1800-$4000; the most basic offering here weighs in at 280#.

Digital Converter

The other option is to use a digital converter that uses large capacitors to provide the storage to timeshift the power, and electronic circuitry to convert that into sine waves on the other phases. Because of the greater design complexity and expensive components in the large capacitors, a digital converter is typically more expensive to buy, but it has lower ongoing operational costs, and for my setup in particular, lower installation costs due to my ability to locate it closer to where the power is needed and closer to the main panel.

PhasePerfect is one supplier of digital converters; their 10HP 230V models range from $3500-$5900, depending on the enclosure type, cooling support, and robustness. And the $3500 one weighs about 60#, about 20% of the weight of an equivalent-sized rotary converter. They also have 460V offerings that have integral upconverters to deliver 460V output given a 230V input, vs. needing an external transformer to do the upconverting if you were to go the rotary converter route.

Other Phase Converters: VFD and Static

There are two other types of phase converters, both with their advantages, but neither appropriate for large motors integrated into other systems.

A static phase converter is used to generate 3 phase power during the starting of a motor. A static phase converter consists of one or more start capacitors and a start relay. The start capacitors produce electricity across the third winding of a motor during start up, once the motor is up to speed these capacitors are disconnected from the motor winding. The motor load is now running on just the two single phase lines of power (in essence, the motor is single phasing). There is at least a 1/3 power loss of the motor horsepower and they cannot run inductive or resistive loads, but these are very inexpensive (i.e.: about $250 for a 10HP model from North American Rotary).

A variable frequency drive (VFD) converts single phase to three phase power via a digital system, and also adding in features that allow the motor speed to be controlled as well. Galt G200 series and Mitsubishi D700 & E700 series all have VFDs that come from the factory ready to operate on single-phase input power and create three-phase output power to run an induction motor, and I have one from a Chinese company controlling the 2KW spindle on my CNC. They are good only in setups where the output is connected only to a motor. In those situations, a VFD allows you to set the motor speed (i.e.: for an irrigation pump, or CNC spindle) at exactly the right setting for your needs. But if the motor is part of a machine that also has digital circuitry, relays, etc. incorporated, then you could damage that circuitry by using a VFD. A 10HP model from American Rotary (distinct from North American Rotary) runs about $1000.

My Setup

As suggested by the text and tradeoffs mentioned above, I went with a 10HP digital converter from Phase Perfect. It was relatively easy to install, running an 80A circuit from my main panel (thru conduit) in my shop to the converter.

All the pieces together: dust collection port; phase converter (lower right) & electrical panel.

25A three-phase breaker for my planer, and a three-phase surge protector from Siemens, still provides ample space for either two more three-phase devices (or just two more 240v single-phase tools).

Though I could potentially connect the planer directly to the phase converter as it is the only three phase device I own, I elected to add an electrical panel that will potentially allow me to add additional three phase devices in the future. Using a panel also allowed me to insert a few surge protectors into the circuitry as well, to reduce the risk of a power surge on the house (perhaps from a lightning strike or electrical failure from a wildfire) making it all the way thru to the very expensive planer at the end of all this wiring.

Finally Ready!

Everything is finally all set up for the arrival of my planer, which I will cover in the next post.