Most of the smaller stuff I build is not “structural”, nor does it use a lot of material. But the bigger pieces - from built-ins to free-standing furniture - has to hold up to its own weight as well as years of use (and abuse).

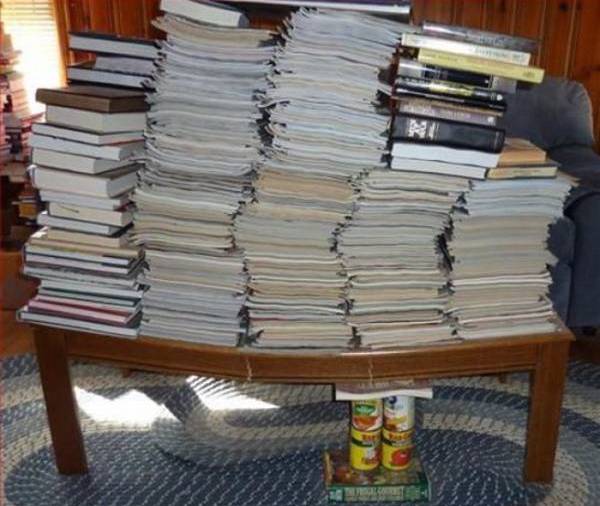

How do we make sure those shelves don’t sag, or the floating countertop is solid? In this first post I’ll share pointers to several useful calculators, and touch on good guidelines and a few techniques to avoid finding yourself with a beautifully crafted piece of furniture that, under duress, starts looking like this!

How Much Sag is Too Much

You will probably notice deflection far before it gets to the sorry state of that coffee table! 1/32″ (0.03″) per running foot, or 3/32″ (0.09″) for a 3′ wide bookshelf or table, is typically visible. And over many years, the sag of a shelf tends to increase by as much as 50% as it is stressed repeatedly in the same direction. So a good target for initial allowable sag is 0.02″ per foot or less.

Don’t Worry About Small Shelves

Many cabinet designs call for the flexibility of adjustable shelves. Unfortunately, however, adjustable shelves are more prone to sagging than fixed shelves, as anyone who has loaded a cheap Ikea bookshelf with all of their college textbooks can attest. This is a consequence of many factors in that $50 hand-me-down bookcase. But with a bit more planning and design consideration (and better materials), sagging can be wholly avoided.

However, for “small” shelves, sag is not really a problem and one can just ignore considerations of sag for typical loads. What’s “small”? The most frequently used quality materials for custom-built wood shelves are 3/4” thick plywood, poplar, or pine; definitely avoid the melamine-laminated composite shelving and MDF. And a typical shelf load to plan for is 20-40# per foot - libraries often plan for 35#.

A 30” wide adjustable shelf that is 10” deep, made of any of these three (plywood, poplar, pine) materials, will have an acceptable sag for a load of up to 35# per foot, or about 90# for the entire shelf. Make it of poplar - the stiffest of those three materials - and you can make a narrower adjustable shelf, down to about 8”, still without any problems. Deeper or shorter shelves? Or anticipating less weight? Sag definitely won’t be a problem for those small adjustable shelves.

Narrower shelves aren’t as strong, however. But fortunately, as you get narrower, it’s less likely that you’ll get to 35# per foot. A 6” deep adjustable shelf will probably not get loaded more than about 20# per foot - made of any of those materials, a 30” span would still be fine.

Of course, if you’re loading your shelves like that coffee table above, all bets are off!

The Sagulator

Wood Bin’s Sagulator wood sag calculator

But - what if the design calls for something outside these “small” shelf guidelines? Higher weight capacity, or longer or narrower shelves? Then, it’s time to break out a calculator. But don’t worry - these are online calculations that hide the messy math, at least to start out with!

I’ve come across a few calculators online, but the Sagulator seems to be the best one so far for ease of use, flexibility, and options that allow for common solutions that woodworkers use to counteract sagging shelves. Select the material, enter a few numbers, and voila, it estimates the total and per foot sag, and even makes a judgement call, summarizing the results as one of Excessive, Borderline, or Acceptable.

Counteracting Sag

If your design sags too much, there are a few simple solutions, and a few more involved design changes. Let’s assume, however, that changing the size of the shelf, and how much load or weight you need it to support, is not an option.

For the examples below to give a sense of how much each design change can help, let’s focus on a 10” deep shelf, made of 3/4” thick plywood shelf. And let’s assume a typical 30# per linear foot load. Then we can find the maximum width shelf that will give an initial sag of 0.02” per foot.

Different Material

Some materials are just stiffer than others. Of the three most common for basic shelving - poplar is the stiffest, with pine and plywood just slightly less stiff (or, in engineering-speak, having a lower modulus of elasticity). However, switching to even less elastic (and more expensive) oak could push your design into safe territory; if the shelves will be painted, the material choice is almost irrelevant except for cost (and availability).

Pine (spruce): 28”

Plywood (fir): 28”

Poplar: 28”

Oak: 32”

If budget is no barrier, a beautiful hardwood like purpleheart is even stiffer, and could get you a 35” wide shelf, but that would be a very unconventional (and wasteful) use of that expensive wood!

Thicker Materials

Though Lowes or Home Depot only carries boards in 3/4” thickness, and plywood thicker than 3/4” is not very common, you can usually find thicker materials at a specialty lumber store. If you go to 1” thick material instead of 3/4”, that gets you another 10” or so of width.

Pine (spruce): 38”

Plywood (fir): 38”

Poplar: 41”

Oak: 42”

Edging Strip

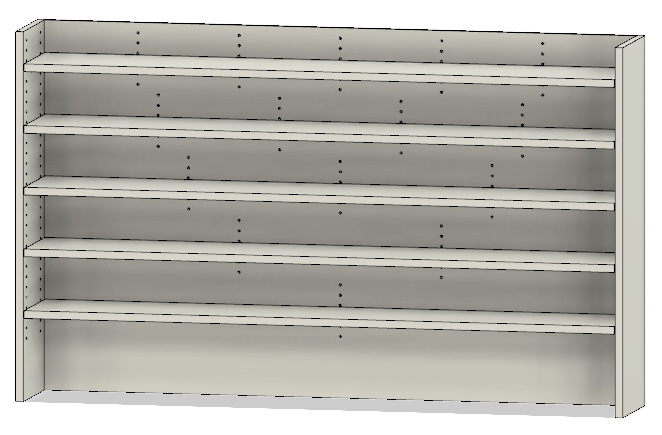

Cosmetic edging strip

An edging strip - typically, a solid piece of wood - can be fastened to the front edge of a shelf. Occasionally, this may be strictly a cosmetic element, such as that applied to the sides of a plywood shelf in order to “finish” the edge. If it’s the strip is no thicker than the shelf itself, it doesn’t really add any strength to the shelf.

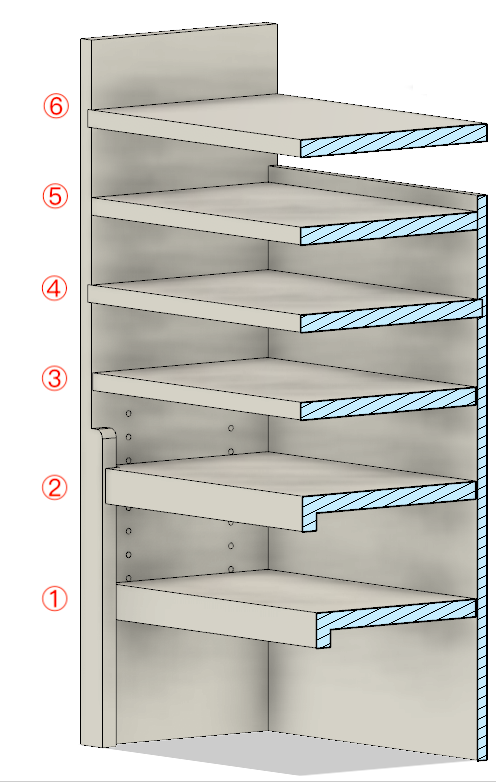

However, when made thicker / taller, it often helps the shelves blend in more seamlessly to the rest of the cabinet system and show more heft and mass. The edging strip can be of the same material or a different material - often the shelf will be a dimensionally stable and inexpensive plywood, and the strip might be a slightly more expensive solid wood like poplar. See styles #1 & #2 in the diagram below for examples of a recessed edging strip and flush edging strip.

And that edging strip also need not have just a simple rectangular shape; it could be rounded, have a beaded profile, or… the imagination (and available router bits) is the limit.

That adjustable plywood shelf that sags 0.02”/foot when 28” long could be extended to:

34” with 3/4” thick by 1-1/2” tall poplar edging strip (most common size and material for paint grade)

35” with same strip made of oak instead

37” back to poplar, but 1-3/4” tall instead of 1-1/2”

Fixed Shelf

Is that still not a wide enough span? If we’re talking about furniture, countertops, or similar, a steel structural element may be the way to go. But if that’s not an option due to cosmetic or other reasons, really the only option left is to make those shelves fixed instead of adjustable. A shelf that is fixed - whether by glue, screws, a dado cut, or a combination of these methods - is held at a right angle to the upright, whereas a shelf that is resting on pins or brackets can flex much more easily.

Shelves that are also fixed to the back of the cabinet (style #4 in the diagram below) add additional strength to the shelf as well.

Three styles of adjustable shelves (#1 - #3), and three styles of fixed shelves (#4 - #6).

Shelves fixed only at the two ends such as for an open see-thru display cabinet, or due to limits on how the cabinet is being constructed, there are more strict limits to the width of the shelf.

Returning to the earlier example of a plywood shelf without any edging strip, that 28” span could expand to a 48” span if the two ends (but not the back) were fixed instead of adjustable - shelf style #6 in the diagram above.

Or put all these things together: shelf fixed at the two ends, made of 1” thick oak, with a 1-3/4” tall 1” wide oak edging strip. That get’s you an 84” wide shelf that would easily support 30#/foot, or 210# in all, without any visible sagging.

Embedding Steel

Finally, we get to the idea of embedding steel. This is generally not an option for built-in shelves because the steel might be unsightly in traditional wood cabinetry, and a standard 3/4” thick board does not provide enough depth for a meaningful steel element to be embedded. But for other types of furniture, this might be able to be hidden - or perhaps could even add to the aesthetic.

Steel has a whole bunch of other considerations, and these are all beyond the capabilities of the Sagulator. So read on…

Shape & Weight

Steel is available in loads of shapes…

There is probably a few semesters of university level mechanical engineering here, so I’ll stay away from the theory. But in short, hollow shapes like a square, round, or rectangular tube, an I-beam, or even just an “L”-shaped “angle iron”, give a lot of strength without taking as much weight as a solid shape.

And the more solidly the steel is affixed to the element it’s supporting, the more effective the combined system will be in resisting forces. I recently installed a solid maple hanging countertop to hidden / embedded steel angle iron by screwing it in every 4”. Or liquid nails or a similar adhesive can be liberally applied along the entire length.

These are all great guidelines and help provide some intuition, but we want to get to something a little more concrete.

Steel Sag Calculators

Because of the range of shapes and sizes that steel can be purchased in - and the fact that it is a more uniform material used in a greater range of critical structural designs - there are many calculators that unfortunately are not as user friendly as the wood-focused Sagulator.

This is the best calculator I’ve found so far, but it requires a few additional inputs that take some effort to find or calculate.

Modulus of elasticity: this is a property of the material, such as steel or copper. The default value is a good starting point; this table lists a few other metals.

Load on the beam: this value represents the center-loaded weight for the entire shelf; typically the shelf or beam would have a uniform weight distribution. A center load puts more stress on an element than a distributed load so designing for this would be very conservative. And the value expected here is the load over the entire shelf, not the load per unit length.

Moment of inertia: this is a property of the cross-section of the steel, such as a hollow tube or angle iron; this site allows you to select the shape, and then enter the key dimensions of the shape; be sure to use inches, to match the only units supported by the “Easy Calculation” tool. The moment of inertia resisting sag is the value in the “Moment of Inertia Ixx (unit^4)” field.

The CivilEngineer website has plenty of moment of inertia calculators for most common shapes

Supporting the Shelf on Three Sides

What if the shelf is supported on three sides, rather than two? In my projects, this has come up as potential elements to calculate in a few designs. Two recent examples:

How much might a “floating” bathroom countertop sag (secured at the back and two ends), given it has a very heavy concrete sink?

Can we get a very wide adjustable shelf, that would sag too much if only supported on the two ends, but perhaps could become possible if we put some adjustable pins in the back of the cabinet as well?

And the first of these questions ended up being irrelevant: even with a ultra-conservative 300# load, the 2-1/4” thick maple countertop would sag less than 0.01” per foot, according to the Sagulator. In fact, we could almost double the length before sag becomes an issue. Add to that the fact that it would be fixed to the back as well as the two ends, and this one will definitely not sag.

eFunda Calculator Fail

The eFunda (Engineering FUNDAmentals) three sided supported plate steel sag calculator

However, if we needed to calculate this sag for a countertop (i.e.: shelf) fixed on three sides, this calculator comes close to helping.

The main difference in the second question is that the sides are adjustable or “simply supported” in engineering speak, rather than fixed. This calculator comes close to answering the question where the sides are not fixed.

For both, the required inputs include the modulus of elasticity, touched on earlier, as well as the poisson ratio for the material. For woods, the modulus of elasticity for many species can be found in The Wood Database, an excellent website (and print book). The poisson ratio is a bit harder to come by, though chapter four (Mechanical Properties of Wood) of the Wood Handbook, a USDA publication available for free as well as in print, lists the values for some species. It turns out the results aren’t very sensitive to the poisson ratio (so long as the value is around 0.3).

Both these “three side” calculators have three major issues, however, that limit their applicability:

if the length of the shelf is more than 4x the width, the results come with a warning that the approximations used may not work for this problem; indeed, I got some non-intuitive results with a shelf length 6x the width.

This doesn’t instill confidence in the results.

some species poisson ratios are far outside the 0.3 around which the calculator is fine-tuned

want to use it for more than three or four calculations? you better sign up for an account!

Fusion360 Fail

But wait! Fusion360, in which I do all of my photorealistic rendering, and much of my CNC designing (see this blog entry), does robust engineering analyses. Granted, it isn’t as straightforward as a calculator, but for those larger projects with structural uncertainty, it is probably worthwhile to model and verify, rather than to find out too late the design will fail.

In writing this blog, I got so excited by this solution that had been lurking on my laptop all along, so I designed a simple but super wide adjustable shelf to test it out, putting in a few different options for how many pins to provide for back support over the 5’ span.

This screenshot of the results shows what would happen if the shelf were made of ABS Plastic. Or I could choose any of a variety of other plastics, copper, one of dozens of steel grades, or other metals and engineered / refined products.

A shelf made of polystyrene just won’t cut it!

But no wood species can be modeled - the material properties aren’t defined in Fusion360. Or more specifically, at present, only isotropic materials can be modeled. That’s a fancy way for saying that wood strength depends on the direction of the grain, which is far more difficult to model than uniform materials like plastics and metals.

Opportunity for Future Online Tool

So it seems this is an area where - at least at present - detailed analysis will depend either on a (typically in the low thousands of dollars or more) professional structural engineering evaluation, or more likely given that high cost, intuition and overdesign to avoid potential problems.

Do you have a structural engineering background? Want to conquer this area for all posterity to benefit? I’d love to partner with someone to make a new calculator available to the woodworking community!